How to Select the Right Ball Valve for Industrial Applications: A Complete Guide

- News

You will need to select the correct type of industrial ball valve for smooth operations, safety, and efficiency in industry applications. Be it a manufacturing plant, hydraulic system, or high-pressure fluid network, the right valve is helpful in accurately controlling the flow and averting costly downtime.

This comprehensive guide will walk you through everything significant in selecting just the ideal industrial ball valve for your application, and how a trusted ball valve supplier like VB Industrial Supply can help make the right decision.

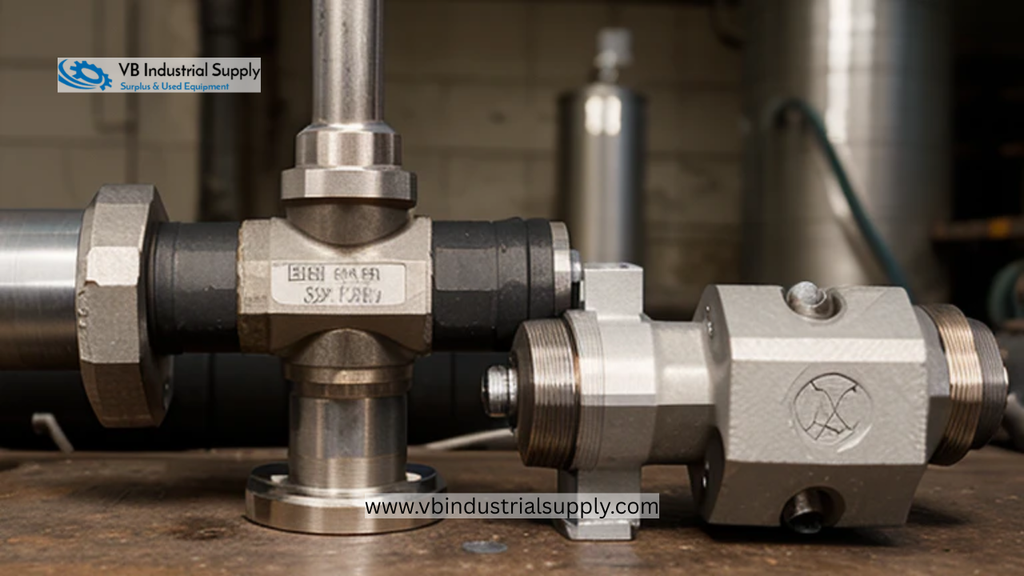

What is an Industrial Ball Valve?

An industrial ball valve is a precision-engineered component designed to control the flow of liquids or gases through a pipeline. It contains a spherical ball with a hole through its center that opens or closes when the valve handle is turned. This design provides a tight seal, minimal leakage, and quick shutoff-something ideal for applications needing dependable control and durability.

Industrial ball valves are widely used in the following:

- Oil and gas

- Chemical and pharmaceutical processing

- Power generation

- Water treatment

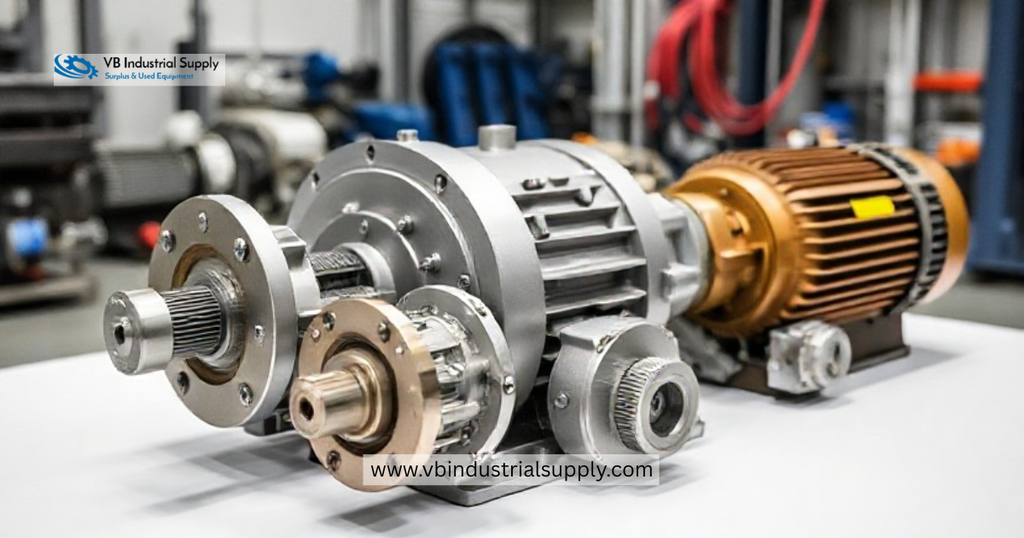

- Manufacturing and hydraulic systems

Our hydraulic valves, among the series of ball valves, serve high-pressure applications in heavy industry.

Types of Industrial Ball Valves

The different types of valves available have to be known first when choosing the right valve:

Full Port Ball Valve

Provides full flow without pressure drop. Applications needing high efficiency in flow require this.

Reduced Port Ball Valve

Slightly narrower than the pipeline can develop some pressure drop, but it is often more economical for general applications.

Floating Ball Valve

Uses a ball that floats slightly downstream to press against the seat for a tight seal. Common in low- to medium-pressure systems.

Trunnion-Mounted Ball Valve

The mechanical anchoring on both ends of the ball is a design feature, making this valve highly suitable for high-pressure applications such as in oil pipelines or large industrial systems.

Three-Way and Multi-Port Valves

They have the tendency to regulate fluid flow in more than one direction and are suitable for complicated systems where flow diverting or mixing is required.

Critical Considerations in the Selection of a Ball Valve

Selection of the right industrial ball valve requires consideration of a number of technical and operational parameters. The following are some of the key parameters:

1. Material Compatibility

Ball valves can be manufactured from a number of materials, including:

- Stainless Steels: Very good corrosion resistance in chemical and high-pressure applications.

- Brass: This is used for low- and medium-pressure applications of water and gas.

- PVC or Plastic: Low-cost and lightweight for water or other non-corrosive fluids.

For industrial applications, either stainless steel or carbon steel is often ideal because of its strength and harsh environmental resistive capabilities.

2. Pressure-temperature ratings

Always check the valve pressure and temperature limits to ensure that they will be within what is acceptable to your system. VB Industrial Supply hydraulic valves are for use in high-pressure situations where reliability and safety are paramount.

3. Valve Size and Flow Requirements

Diameter directly impacts both flow rate and pressure, so be sure the valve is properly sized based on your pipe size and process to maintain the best system performance.

4. Actuation Method

Ball valves are able to be operated manually, electrically, or pneumatically.

- Manual valves are best for simple on/off control.

- Automation or remote control applications, by contrast, are better suited to electric or pneumatic actuators.

5. Seal Type

Select valves with seals made for the type of fluid involved in the process. In some cases, PTFE seals are good for chemical resistance, and reinforced seals show good results in high-pressure systems.

Industrial Applications That Rely on Ball Valves

Ball valves find use in a great number of important industries, including the following:

- Hydraulic systems control the flow of oil and fluid under pressure.

- Water treatment plants: control chemical dosing and filtration flows.

- Manufacturing plants: These allow for the precision control of process lines.

- Energy and oil refineries: Control high-pressure gas and liquid processes.

Each of these applications requires reliability, and that is where VB Industrial Supply hydraulic valves excel in providing consistent performance under extreme, mission-critical environments.

Maintenance Tips to Extend Valve Life

Even the best valves require good maintenance to function optimally. Here's how to extend their lifespan.

- Leak or corrosion should be checked regularly.

- Regularly clean the valve seats and seals.

- Operate valves periodically to prevent sticking.

- Replace worn-out seals prior to failure.

Routine care not only extends the service life but also ensures the operating efficiency of your system.

Final Thoughts

The selection of an industrial ball valve isn't just about the product choice-it's about investing in performance, safety, and dependability. Be it the replacement of a high-pressure hydraulic valve or finding a general-purpose stainless steel model, the right choice would mean seamless operation across your industrial systems.

At VB Industrial Supply, we make it easy to find exactly what your application requires. Browse through our entire collection of valves, for durable and efficient solutions that will specifically suit the needs of your system.

FAQs

1. What is the main purpose of an industrial ball valve?

It serves to regulate the flow of liquids or gases within a pipeline and provides for reliable shut-off and flow control.

2. How do I choose between a full port and a reduced port valve?

Choose a full port for minimal pressure loss and a reduced port for cost-effective control in low-pressure systems.

3. Can VB Industrial Supply valves be used for high-pressure applications?

Yes, especially our hydraulic valves, which are intended to perform under extreme pressure.

4. What materials are best for industrial ball valves?

Stainless steel and carbon steel are preferred for their strength and resistance against corrosion.

5. Do ball valves require regular maintenance?

Yes, periodic cleaning and inspections support their extended service life while maintaining performance.