A Comprehensive Guide to Industrial Instrumentation: Tools, Techniques, and Best Practices for Enhanced Operational Efficiency

- News

In today's global industrial market competition, efficiency of operation is not an objective — it is a requirement. Across the board, from manufacturing and energy to chemical processing and food processing, repeatable quality, minimized downtime, and maximum utilization of resources are the success factors.

Industrial instrumentation lies at the foundation of this performance: hardware, methods, and technologies used to monitor, measure, and control industrial processes. This blog drives the mystique from the basics of industrial instrumentation, introduces basic tools, discovers successful methods, and reveals best practices for maximizing productivity.

What Is Industrial Instrumentation?

It is an art and science of measuring, monitoring, and controlling process variables in industrial processes. Some examples of process variables are pressure, temperature, flow, level, pH, and electrical signals.

The principal aim is:

- To provide safety through the alarm of abnormal conditions.

- To provide product quality through accurate control.

- To maximize efficiency through minimized waste and downtime.

- To enable automation and real-time decision-making.

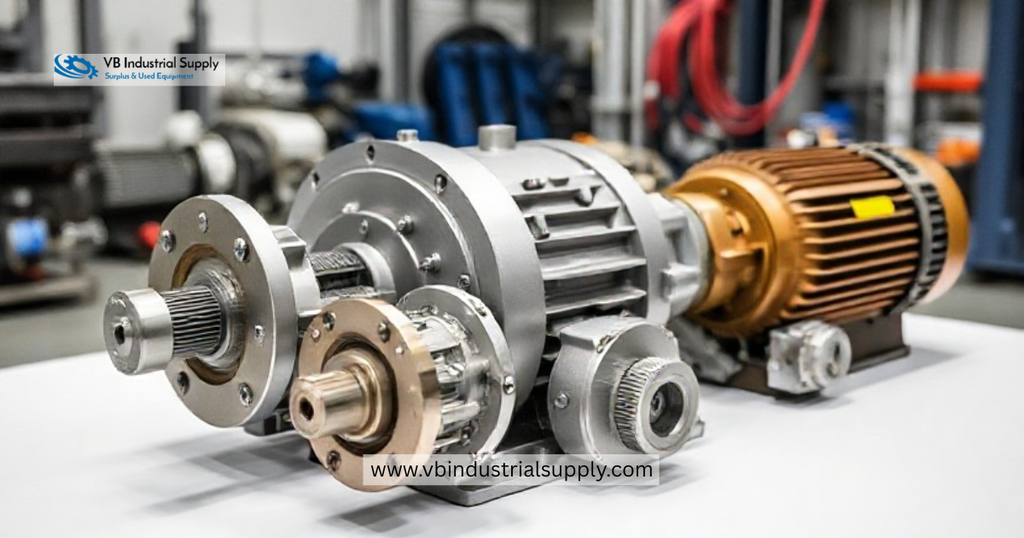

Instrumentation Tools Key to Industry

There is an immense variety of instrumentation equipment employed in all industries. Most frequently used ones are:

Sensors and Transducers

Sense physical changes like pressure, temperature, or vibration and transform them into electrical signals.

Pressure Gauges and Transmitters

Measure system pressure to allow equipment to be operated safely.

Flow Meters

Measure the liquid, gas, or steam flow rates within pipework.

Temperature Controllers and Thermocouples

Offer true readings and regulation of heating and cooling procedures.

Level Instruments

Application in tanks and silos for measuring fluid or material levels.

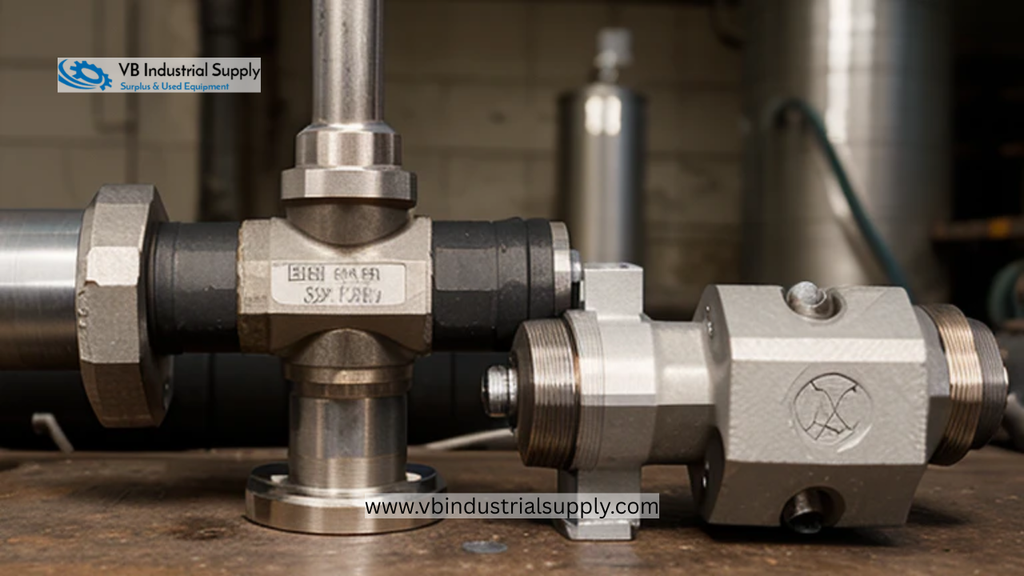

Control Valves and Actuators

Regulate the flow, pressure, or temperature of process conditions automatically.

Signal Conditioners and Indicators

Convert raw sensor signals into useful formats for operators or control systems.

Data Acquisition Systems (DAQ)

Accumulate and record process data to optimize performance and monitor.

This equipment works in concert to keep industrial processes stable, efficient, and secure.

Techniques of Industrial Instrumentation

Aside from equipment, process instrumentation methods control and monitor processes. Some of the most common approaches are:

Calibration

True readings from verifiers are provided by standard reference comparisons.

Closed-Loop Control Systems

Self-correcting feedback systems, where instruments automatically control processes to meet specific conditions.

Signal Processing

Removal of noise and preparation of raw data to enhance accuracy by smoothing.

Predictive Monitoring

Use of sensor signals and analytics to identify potential equipment failures before they happen.

Integration with SCADA and PLC Systems

SCADA and Programmable Logic Controllers (PLCs) provide central process control and automation.

Best Practices for Increased Operational Efficiency

1. Choose the Right Instrumentation Tools

- Pick instruments that suit your particular process conditions (temperature range, pressure rating, chemical compatibility).

- Ensure equipment and tools conform to industry standards like ISO, ANSI, or IEC.

2. Periodic Calibration and Maintenance

- Create a schedule for calibrating important sensors and devices.

- Preventive maintenance minimizes downtime and maximizes equipment lifespan.

3. Value Data Accuracy and Integration

- Employ accurate transmitters and signal conditioners.

- Data interoperable with PLCs, SCADA, or cloud platforms to enable real-time analytics.

4. Invest in Training and Safety

- Train the operators to comprehend instrumentation tools and interpret measurements correctly.

- Safety-oriented practices minimize the chances of accidents due to instrumentation failure.

5. Digitalisation and IIoT

- Utilize the Industrial Internet of Things (IIoT) for predictive analytics and real-time monitoring of maintenance.

- Wireless instruments and intelligent sensors make remote monitoring possible with cost savings.

6. Collaborate with Quality Suppliers

- Buying quality parts such as gauges, control systems, and sensors makes reliability possible.

- Suppliers such as VB Industrial Supply offer high-quality instrumentation equipment to meet varied industry demands.

Checklist for Installing Instrumentation System

- Identify key variables (temperature, pressure, flow, level).

- Select appropriate sensors and measuring equipment.

- Install protection equipment (circuit breakers, transformers, power supplies).

- Condition instruments to be compatible with control systems (SCADA/PLC).

- Calibrate all instruments before commissioning.

- Routine maintenance and testing should be planned.

Why Industrial Instrumentation Is Important?

- Productivity – by minimizing downtime and process reproducibility.

- Safety – by detecting threats and avoiding equipment failure.

- Cost Efficiency – through improved energy management and waste reduction.

- Competitiveness – by making automation and improved production quality possible.

Conclusion

Industrial instrumentation forms the bedrock of today's industrial enterprises, allowing companies to monitor, control, and optimize processes with precision and efficiency. By combining effective instrumentation devices, established methods, and industry practice, companies can greatly boost productivity levels while minimizing risks and costs.

If you seek to buy sound instrumentation equipment, sensors, or other components, check out VB Industrial Supply. Committed to performance and quality, they are a tested partner for a boost in industrial development and operational excellence.