Hydraulics vs Pneumatics: A Complete Comparison of Fluid Power Systems for Modern Industrial Applications

- News

In modern industries, both accuracy and efficiency often depend on the choice of fluid power systems. The most favored among these are hydraulic & pneumatic systems, both of which employ fluid pressure to transmit energy and power to equipment.

Although their operational mode are the same, the difference between hydraulics and pneumatics lies in the medium used, performance characteristics, and application appropriateness.

Whether you're developing a new installation or re-encasing existing equipment, understanding hydraulic vs pneumatic systems will help you make the right selection for your industrial use. This blog addresses their fundamentals, advantages, limitations, and application-specific tips, and checklists for related components such as circuit breakers, transformers, and power supplies.

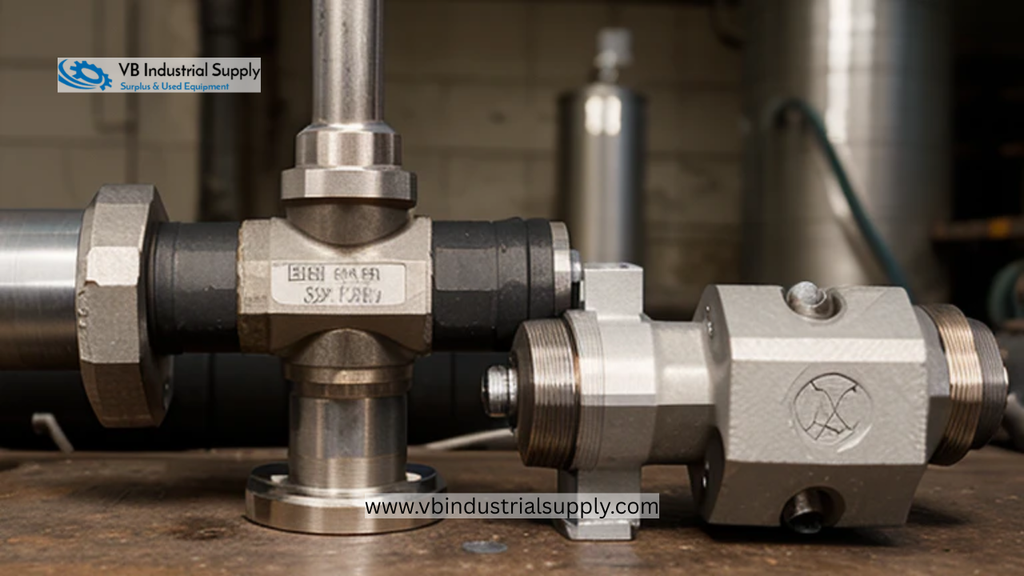

What Are Hydraulics?

Hydraulics use fluid (typically oil) to transmit power under pressure. Incompressibility of liquid enables hydraulics to provide high torque and force, which makes them ideal for heavy machinery.

Key Characteristics of Hydraulics:

- Operates using pressurized liquid (oil or water-based liquid).

- Provides high power output and force.

- Provides smooth and controlled movement.

- Utilized in heavy machinery, construction, aviation, and manufacturing.

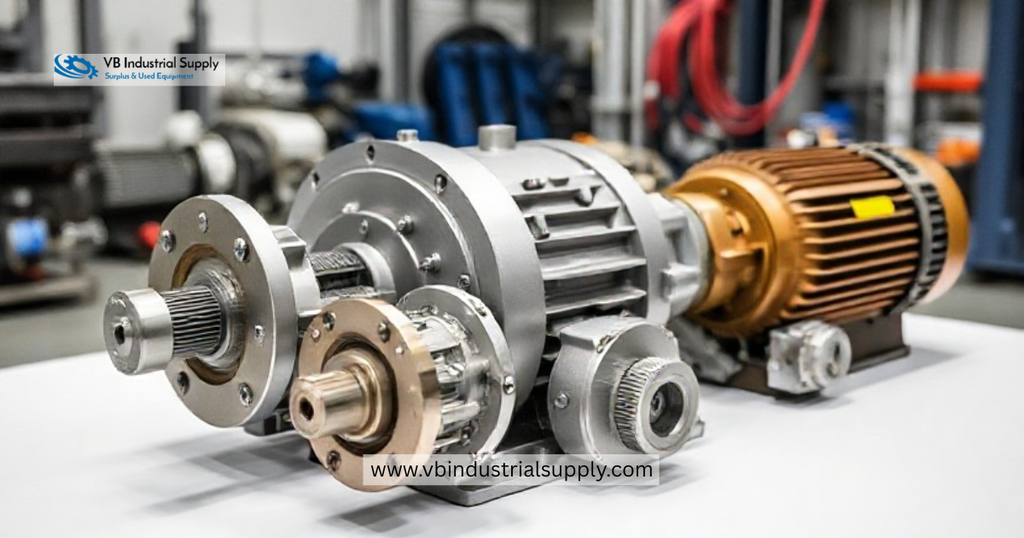

What Are Pneumatics?

Pneumatic systems use compressed air or gas as the working fluid. Since air is compressible, the system is lighter, cleaner, and faster in action.

Primary Characteristics of Pneumatics:

- Operates on compressed gas or air.

- Offers fast and flexible motion, though not as strong as hydraulic power.

- Clean, safe, and economical for small to medium applications.

- Applied in packaging machines, robots, food processing machines, and medical appliances.

Hydraulic vs Pneumatic Systems: A Detailed Comparison

Comparing Hydraulic & Pneumatic Systems, industries must calculate performance, application requirements, and operating cost. Below is a comparison of the differences between hydraulics and pneumatics based on important factors:

| Factor | Hydraulic | Pneumatic |

|---|---|---|

| Power & Force | Provides very high force, ideal for lifting, pressing, and heavy-duty operations. | Limited force capacity; best for lightweight applications. |

| Speed of Operation | Moderate speed, prioritising strength over quick cycles. | Very fast response and movement, excellent for repetitive tasks. |

| Maintenance | Requires regular maintenance to prevent leaks and contamination. | Generally lower maintenance, though air dryers and filters are essential. |

| Applications | Heavy machinery, aerospace, defence, and manufacturing presses. | Robotics, packaging, the food industry, and medical devices. |

| Cleanliness | Hydraulic fluids may leak and require containment. | Cleaner since air is the medium, suitable for sterile environments. |

| Cost | Higher initial cost, but valuable for long-term, heavy-duty performance. | Lower installation cost, but may require more energy for air compression. |

Hydraulics vs Pneumatic Systems: Making the Decision

Hydraulic vs pneumatic systems depend on a few operating requirements. The following are some practical observations:

1. Force and Power Requirement

Choose hydraulics if your application requires heavy pressing, lifting, or high torque requirements. Select pneumatics when your application requires rapid, repeated motion with little force.

2. Accuracy and Precision

Where precision is of prime importance for such applications as CNC machining or aircraft actuators, hydraulics deliver stability and accuracy. Where secondary priority is given to precision for such applications as packaging or pick-and-place robots, pneumatics are the choice.

3. Cleanliness Needs

Pharmaceuticals, food processing, and medical device manufacturing industries prefer applications in a clean, oil-free environment provided by pneumatics. Hydraulics, while more powerful, would be unsuitable where there is a risk of contamination.

4. Operating Speed

Pneumatics operate swiftly and are well-suited for use on automation lines. Hydraulics deliver power but are slower than compressed air systems.

5. Cost Factors

Hydraulics involve greater up-front costs but can be used to perform more arduous tasks with reliability over the longer term. Pneumatics are cheaper to install but potentially more expensive in terms of power since air must be constantly compressed.

6. Maintenance and Safety

Fluid power systems require fluid examination, leak prevention, and suitable handling. Pneumatics are safer, but air line moisture and contaminants must be managed with good filtration.

Basic Components and System Considerations

As you design or maintain fluid power systems, you should also deal with supporting electrical and safety components:

- Circuit Breakers – Protect electrical circuits from overloads and short circuits.

- Transformers – Supply a stable voltage for control systems.

- Power Supplies – Deliver dependable power to sensors, actuators, and control panels.

- Pressure Regulators & Gauges – Deliver steady operating pressure for hydraulic & pneumatic systems.

- Filtration Units – Both oil (hydraulics) and air (pneumatics) are required to deliver long system life.

At VB Industrial Supply, you can shop a large assortment of industrial parts to build and sustain efficient fluid power systems that meet your unique requirements.

Conclusion

The difference between hydraulics and pneumatics lies in the trade-off among speed, cleanliness, precision, strength, and cost. Hydraulics dominate where there is high demand for strength and precision, and pneumatics dominate where there is high demand for speed, safety, and cleanliness.

By carefully analyzing your application needs and considering supporting devices such as power supplies, transformers, and circuit breakers, you can make an informed choice between hydraulic and pneumatic systems.

For expert advice and access to high-end industrial materials, go to VB Industrial Supply — your one-stop shop for modern industrial solutions.